Injection Molding Development Process

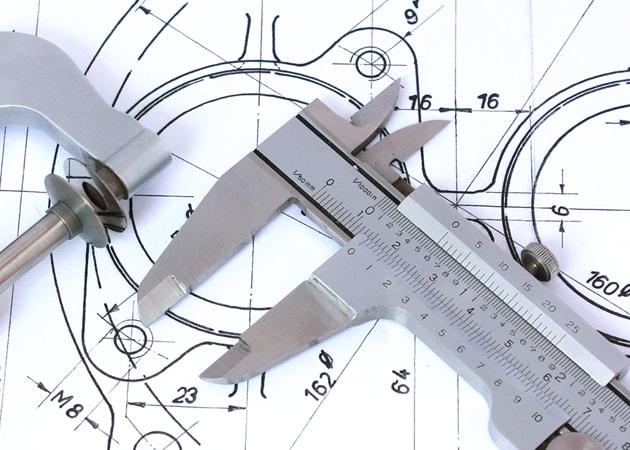

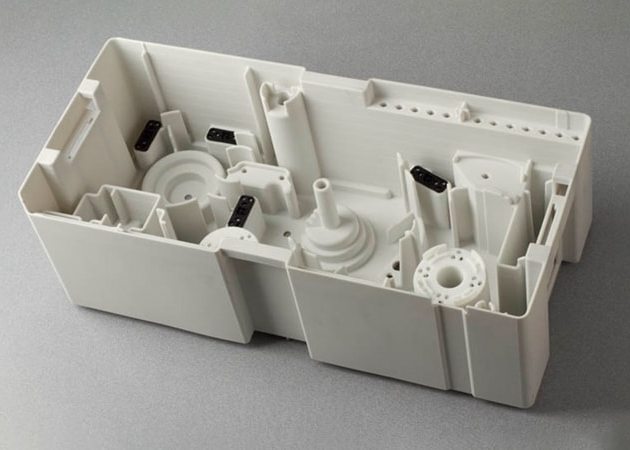

To ensure our injection molding process creates exactly what our clients are looking for, we take each injection molding, urethane casting, and thermoforming project through a step-by-step development process. From designing, to prototyping, then manufacturing, we make sure the finished product lives up to your hopes and expectations. With a passion for designing and engineering unique shipping solutions, PMH INDIA Products has helped companies to reduce density of packaging, reduce ergonomic issues, and more. With a vision system that inspects parts for completion, orientation, and accuracy, your final product will be perfectly crafted every time. From returnable packaging to dunnage, our process will give the results you need.